01 Tándem

Horizontales

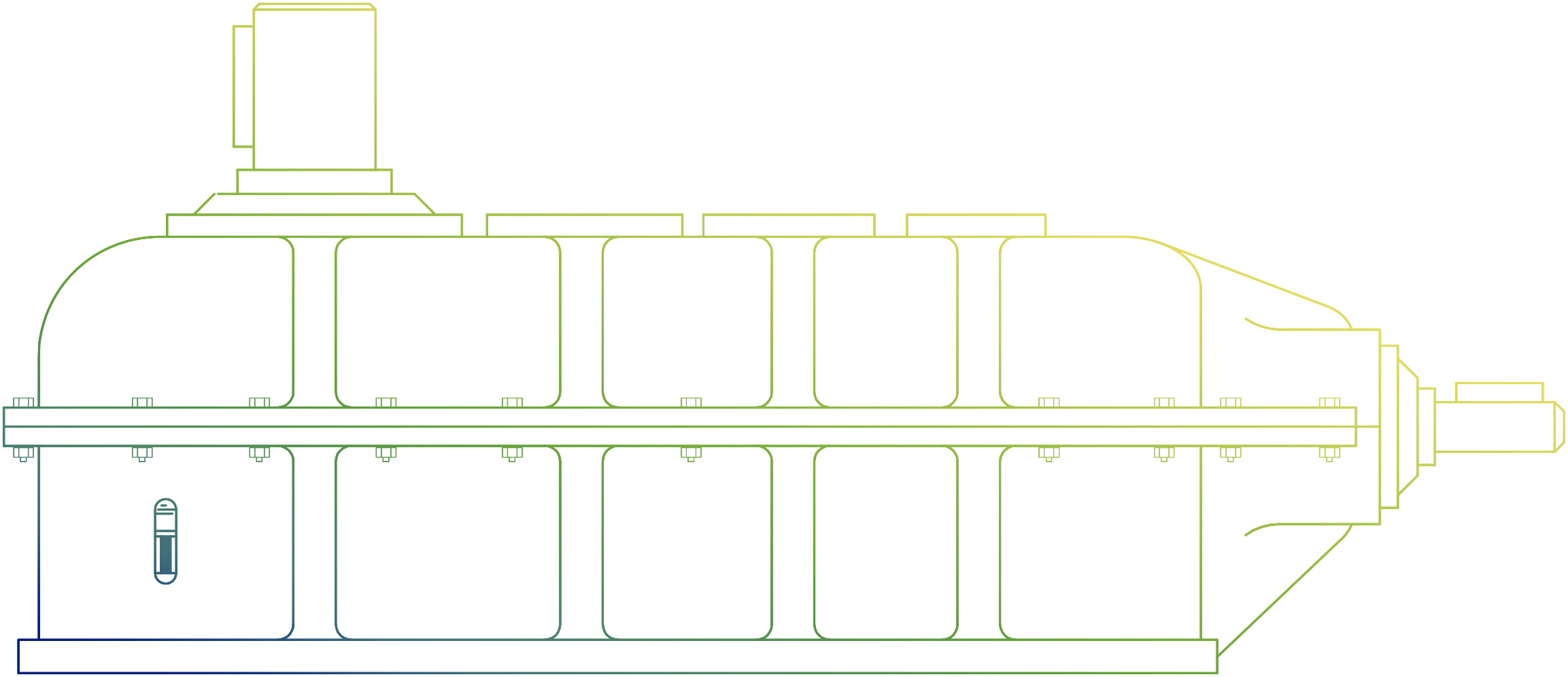

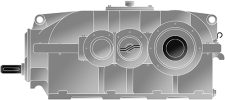

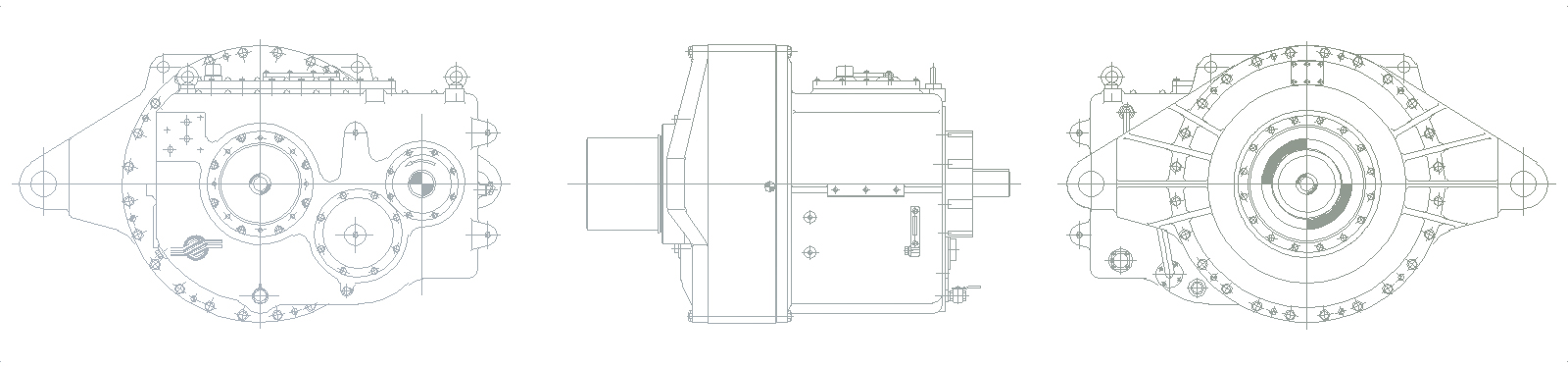

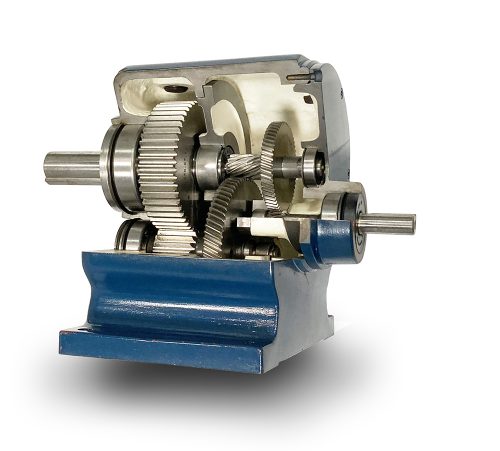

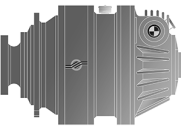

THx

Tándem Horizontal

Ejecución Estándar y Especial

Ejes Paralelos

Nº escalones: 1 , 2, 3, 4

Salida: Eje Hueco o Macizo

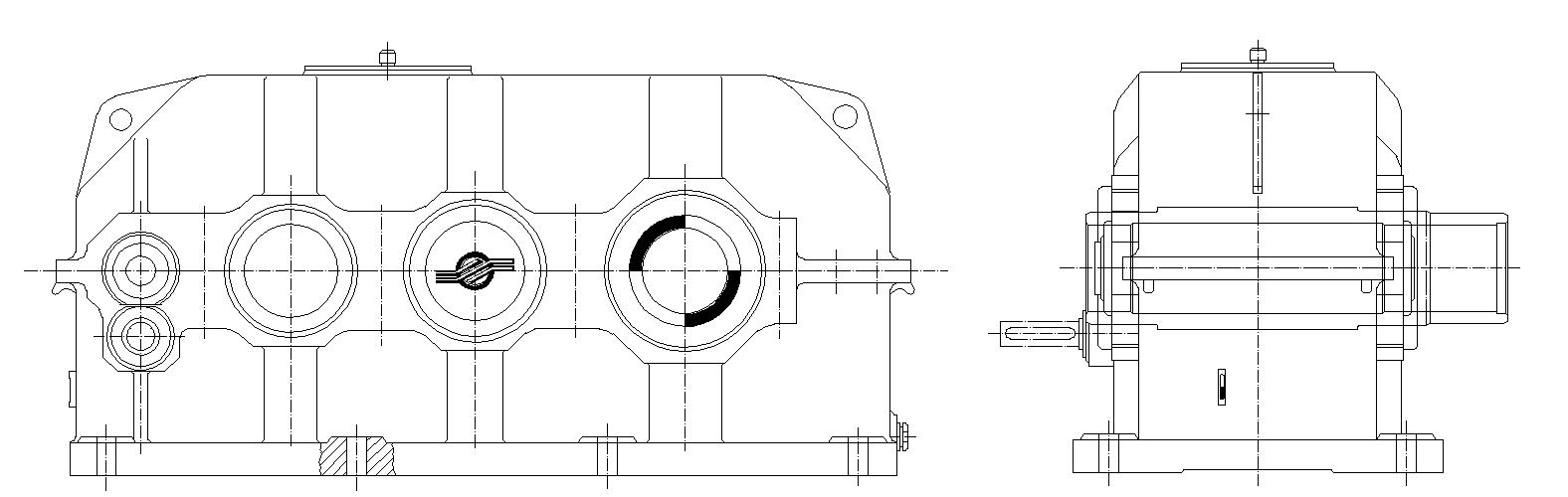

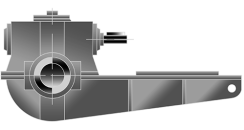

TCHx

Tándem Cónico Horizontal

Ejecución Estándar y Especial

Ejes Perpendiculares

Nº escalones: 1 , 2, 3, 4

Salida: Eje Hueco o Macizo

Verticales

TVx

Tándem Vertical

Ejecución Especial

Ejes Paralelos

Nº escalones: 1 , 2, 3, 4

Salida: Eje Hueco o Macizo

TCVx

Tándem Cónico Vertical

Ejecución Especial

Ejes Perpendiculares

Nº escalones: 1 , 2, 3, 4

Salida: Eje Hueco o Macizo

02 Planetarios

Horizontales

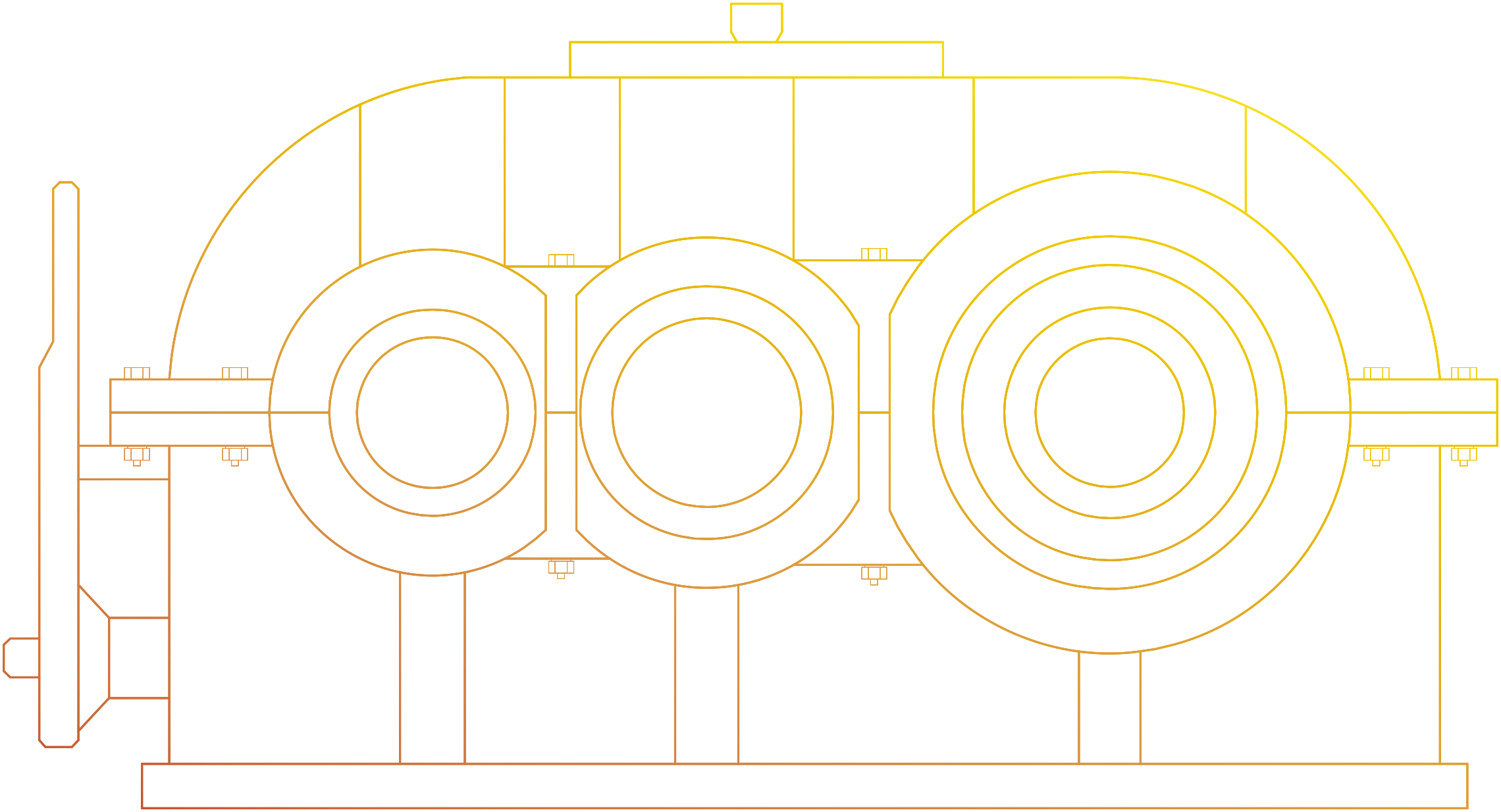

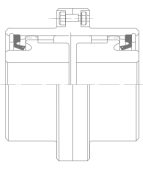

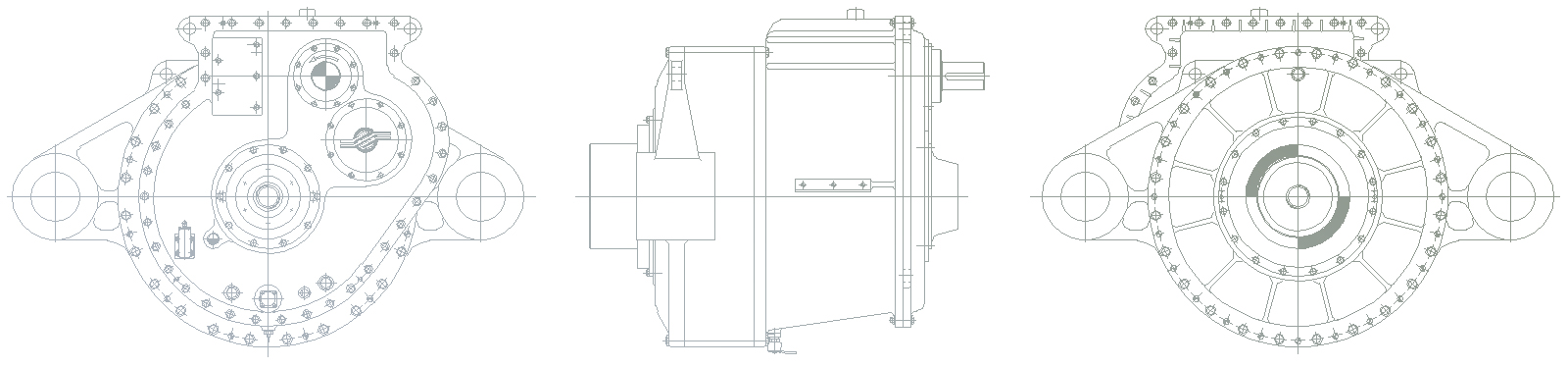

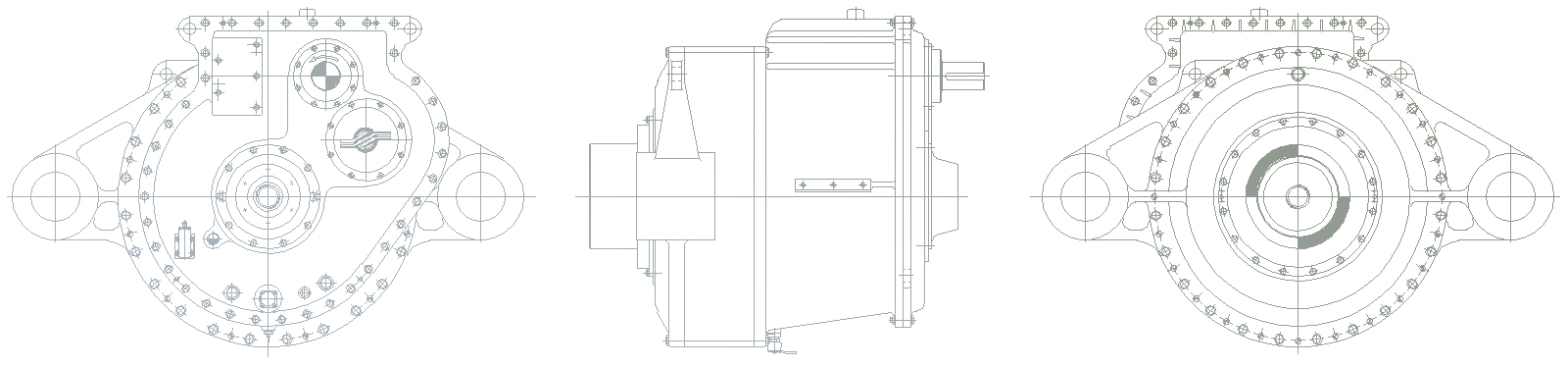

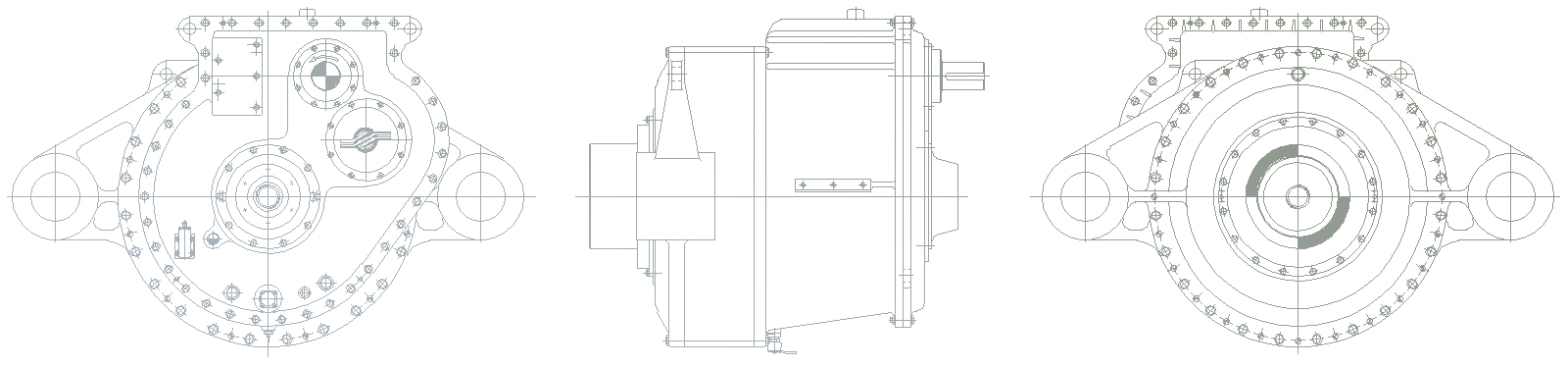

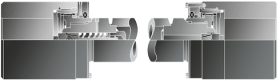

PHx

Planetario Horizontal

Ejecución Estándar y Especial

Ejes Coaxiales

Nº escalones: 2, 3, 4

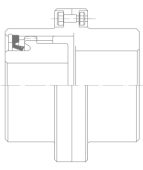

PHTx

Planetario Horizontal Tándem

Ejecución Estándar y Especial

Ejes Paralelos

Nº escalones: 2, 3, 4

PHCx

Planetario Horizontal Cónico

Ejecución Estándar y Especial

Ejes Perpendiculares

Nº escalones: 2, 3, 4

Verticales

PVx

Planetario Vertical

Ejecución Estándar y Especial

Ejes Coaxiales

Nº escalones: 2, 3, 4

PVTx

Planetario Vertical Tándem

Ejecución Estándar y Especial

Ejes Paralelos

Nº escalones: 2, 3, 4

PVCx

Planetario Vertical Cónico

Ejecución Estándar y Especial

Ejes Perpendiculares

Nº escalones: 1 , 2, 3, 4

03 Tándem-Planetarios

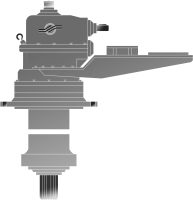

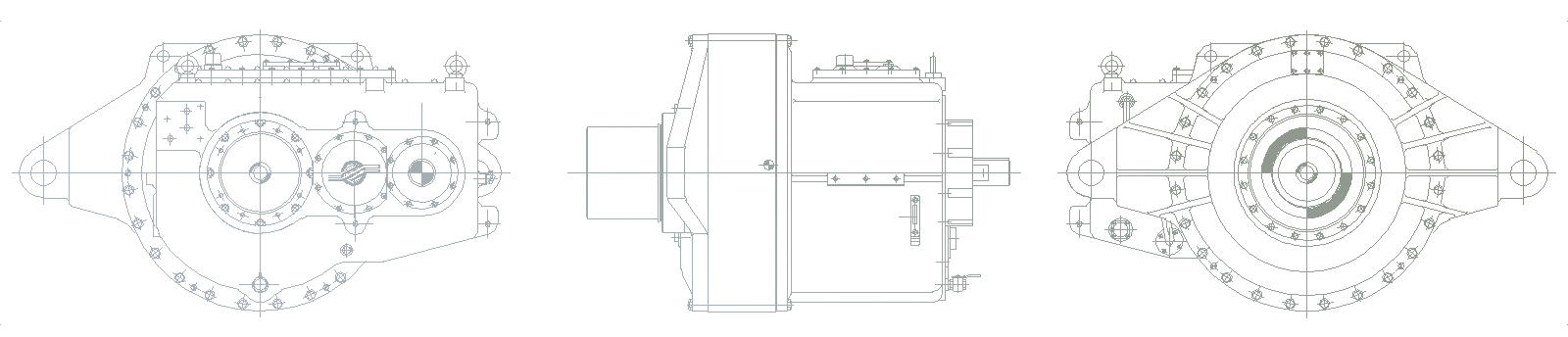

TPHx

Tándem Planetario Horizontal

Ejecución Especial

TPH3

1080V

1080-V

TECNOLOGÍA: GAMESA / VESTAS

Aerogenerador: G47 / V47

Potencia Eléctrica: 660 kW

Potencia Mécanica: 726 kW

Ratio: 52,4135

1080-V1

TECNOLOGÍA: GAMESA / VESTAS

Aerogenerador: G47 / V47

Potencia Eléctrica: 660 kW

Potencia Mécanica: 726 kW

Ratio: 52,3029

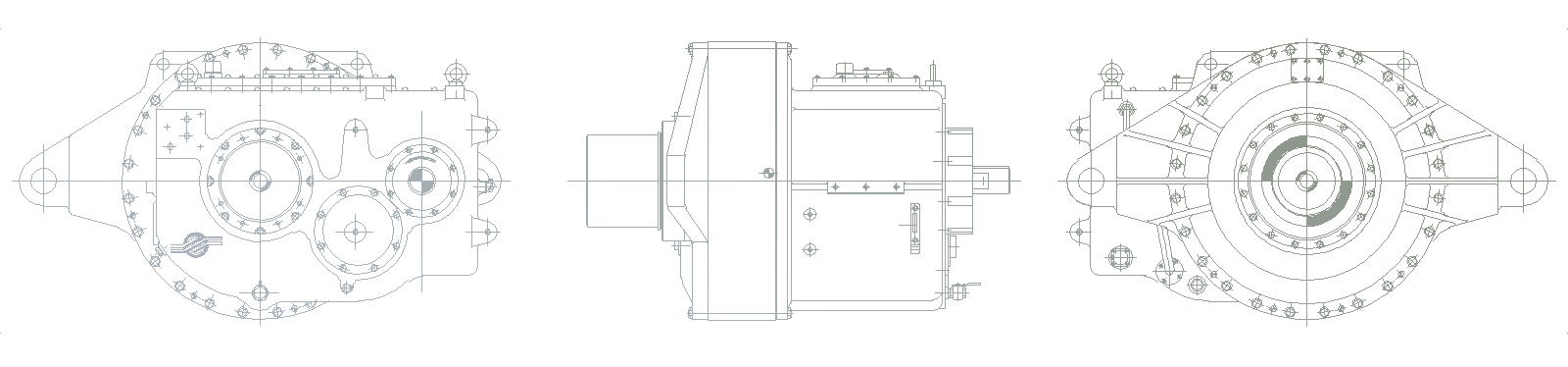

TPH3

109xF

1090-F

TECNOLOGÍA: GAMESA / VESTAS

Aerogenerador: G47 / V47

Potencia Eléctrica: 660 kW

Potencia Mécanica: 726 kW

Ratio: 52,6663

1092-F

TECNOLOGÍA: GAMESA / VESTAS

Aerogenerador: G47 / V47 (60Hz)

Potencia Eléctrica: 660 kW

Potencia Mécanica: 726 kW

Ratio: 58,1751

1095-F

TECNOLOGÍA: GAMESA / VESTAS

Aerogenerador: G47 / V47 (60Hz)

Potencia Eléctrica: 660 kW

Potencia Mécanica: 726 kW

Ratio: 63,1563

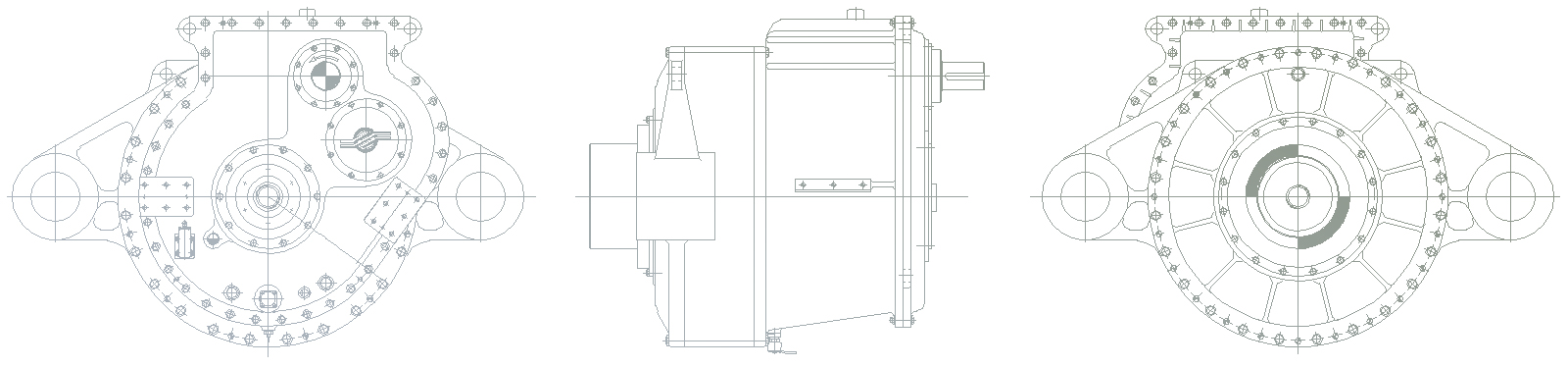

TPH3

1100C

1100-C

TECNOLOGÍA: MADE

Aerogenerador: AE-46

Potencia Eléctrica: 660 kW

Potencia Mécanica: 726 kW

Ratio: 59,856

1100-C1

TECNOLOGÍA: MADE

Aerogenerador: AE-46

Potencia Eléctrica: 660 kW

Potencia Mécanica: 726 kW

Ratio: 59,5924

1100-C2

TECNOLOGÍA: MADE

Aerogenerador: AE-46

Potencia Eléctrica: 660 kW

Potencia Mécanica: 726 kW

Ratio: 59,5924

TPH3

1100G

1100-G

TECNOLOGÍA: GAMESA / VESTAS

Aerogenerador: G52 / V52

Potencia Eléctrica: 850 kW

Potencia Mécanica: 935 kW

Ratio: 61,8125

1100-G1

TECNOLOGÍA: GAMESA / VESTAS

Aerogenerador: G52 / V52

Potencia Eléctrica: 850 kW

Potencia Mécanica: 935 kW

Ratio: 61,8125

1100-G3

TECNOLOGÍA: GAMESA / VESTAS

Aerogenerador: G52 / V52

Potencia Eléctrica: 850 kW

Potencia Mécanica: 935 kW

Ratio: 61,8125

1100-GE

TECNOLOGÍA: GAMESA / VESTAS

Aerogenerador: G52 / V52 (60Hz)

Potencia Eléctrica: 850 kW

Potencia Mécanica: 935 kW

Ratio: 71,8066

TPH3

1150M

1150-M

TECNOLOGÍA: MADE

Aerogenerador: AE-52

Potencia Eléctrica: 800 kW

Potencia Mécanica: 880kW

Ratio: 58,1735

TPH3

1200M

1200-M |.1 |.2

TECNOLOGÍA: MADE

Aerogenerador: AE-56

Potencia Eléctrica: 800 kW

Potencia Mécanica: 880 kW

Ratio: 62,6463

TPH3

1210M

1210-M |.1 |.2

TECNOLOGÍA: MADE

Aerogenerador: AE-59

Potencia Eléctrica: 800 kW

Potencia Mécanica: 880 kW

Ratio: 66,2754

TPH3

1500

1500-E

TECNOLOGÍA: EHN / Bonus

Aerogenerador: EHN1300 / Bonus 1300

Potencia Eléctrica: 1300 kW

Potencia Mécanica: 1430 kW

Ratio: 49,3345

1500-H

TECNOLOGÍA: EHN / Bonus

Aerogenerador: EHN1300 / Bonus 1300

Potencia Eléctrica: 1300 kW

Potencia Mécanica: 1430 kW

Ratio: 59,5779

1500-M

TECNOLOGÍA: MADE

Aerogenerador: AE-61

Potencia Eléctrica: 1300 kW

Potencia Mécanica: 1430 kW

Ratio: 80,5618

TPH3

1600

1600-N

TECNOLOGÍA: ACCIONA

Aerogenerador: AW-1500

Potencia Eléctrica: 1500 kW

Potencia Mécanica: 1650 kW

Ratio: 59,4082

1600-H

TECNOLOGÍA: ACCIONA

Aerogenerador: AW-1500

Potencia Eléctrica: 1500 kW

Potencia Mécanica: 1650 kW

Ratio: 65,7217

04 Motorreductores

Motorreductores

MRx

Motorreductor (Con Motor)

Ejecución Estándar

Ejes Coaxiales o paralelos

Nº escalones: 2, 3

Potencia Nominal: 0,18 a 30 kW

Sujeción: Patas o Brida

RTx

Reductor (Sin motor)

Ejecución Estándar

Ejes Coaxiales o paralelos

Nº escalones: 2, 3

Potencia Nominal: 0,18 a 30 kW

Sujeción: Patas o Brida

05 Sinfín

Sinfín Corona

SCx

Sinfín Corona

Ejecución Especial

Ejes Perpendiculares

Nº escalones: 1 , 2, 3

SCPx

Sinfín Corona Planetario

Ejecución Especial

Ejes Perpendiculares

Nº escalones: 2, 3

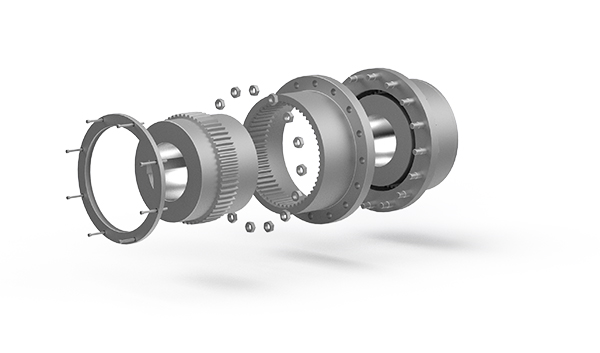

06 Acoplamientos

Serie 1000

Desalineamiento hasta 1º por dentado

Serie 3500

Desalineamiento desde 1º hasta 3,5º por dentado

Serie 7000

Desalineamiento desde 3,5º hasta 7º por dentado

GAMESA, MICON, ACCIONA-WP

los mejores aerogeneradores del mundo equipan FELLAR…

los mejores aerogeneradores del mundo equipan FELLAR…

RENFE Locomotora 269, nosotros diseñamos y fabricamos su trasmisión…

Las excavadoras de ENDESA e UNIÓN FENOSA llevan reductores nuestros…

CEMEX (San Vicente del Raspeig) El reductor de su molino de bolas es de FELLAR…

Menu

Menu

Menu

Fellar, S.A.

C/Villa de Bilbao,6.

Polígono Industrial Fuente del Jarro.

46988, Paterna (Valencia)

ESPAÑA

Teléfono 96 134 05 06

Menu

© 2020 Fellar

C/Villa de Bilbao,6.

Polígono Industrial Fuente del Jarro.

46988, Paterna (Valencia) ESPAÑA

Teléfono 96 134 05 06

Menu